To deliver outstanding quality solar panel while meeting highly customzied demands for solar solutions is the most import thing to us. From raw material sourcing to final outgoing inspection, quality control is carefully monitored. At Blue Solar facility, in-process checkup is an overall effort performed at each stage of solar panel manufacturing. A well-equipped workshop is here for conducting special tests according to industry standards or client’s special specifications. Our quality control system includes:

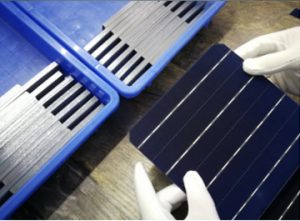

1. Raw Material Inspection:

We will conduct carefull inspection for all the incoming raw material. Appearance and electric performance checking and sorting for quality solar cell, cross-linking tests for quality EVA, and durable testing for backsheet etc.

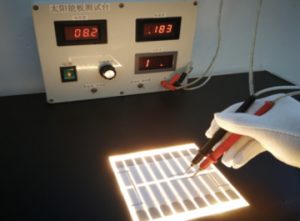

2. Process Quality Control:

Process quality control is carried out with all major machines, by employing control documentation which is exercised at each and every process. The regular inspection practices include EL testing, eletrical performance testing for semi-finished panels, and electrical performance testing for finished products etc.

3. Finished Solar Panel Testing:

Solar Panels are subjected to final tests for verifying compliance with industry standard as well as customer’s specific requirements.

Solar Cell Inspection & Sorting

Electrical Performance Test before Lamination

EL Testing highlights the defects within the solar cells in the solar panel

Electrical Performance Testing

Testing for Finished Panels

Visual Inspection